This is a plant made of four mixers with a capacity of 6000 litres each, equipped with a slow anchor mixer, a turbine on the bottom and three fat smelters with a capacity of 2000 litres, each with anchor mixer. Those mixers, steam heated are fed by two steam generators of 600.000 Kcal/h each and refrigerated by an adequately powered chiller.

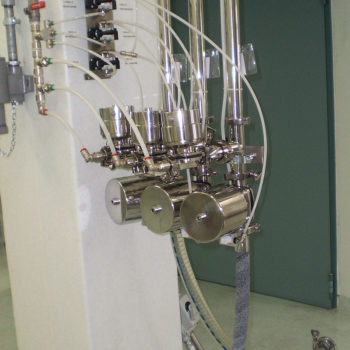

Plant for the production of wetting liquid for wet wipes

The plant consists of a vacuum turbo emulsifier useful capacity 6000 litres turbine on the bottom and slow anchor mixing system, its fat smelter useful capacity 1000 litres, an open air mixer useful capacity 10.000 litres also equipped with turbine on the bottom and its fat smelter 3000 litres useful capacity.

The machines are heated by steam coming from two steam generators of 600.000 Kcal/h each and refrigerated by a chilling tower of 960.000 Kcal/h

The osmotic water needed to produce one batch is dosed by an automatic flowmeter and it is introduced in the mixer already warm as the water pass through an AISI 316 steam/water heat exchanger. This operation allows considerable time saving: in one hour it is possible to have 9000 litres of water at 65°C.

This plant has been constructed according to the latest health regulations and requirements as to satisfy the most demanding customers; this plant has been approved by customers such as Procter & Gambler, Johnson & Johnson and Lever Fabergè.

.

gel production

This is a plant made of four mixers with a capacity of 6000 litres each, equipped with a slow anchor mixer, a turbine on the bottom and three fat smelters with a capacity of 2000 litres, each with anchor mixer. Those mixers, steam heated are fed by two steam generators of 600.000 Kcal/h each and refrigerated by an adequately powered chiller.

Plant for the production of wetting liquid for wet wipes

The plant consists of a vacuum turbo emulsifier useful capacity 6000 litres turbine on the bottom and slow anchor mixing system, its fat smelter useful capacity 1000 litres, an open air mixer useful capacity 10.000 litres also equipped with turbine on the bottom and its fat smelter 3000 litres useful capacity.

The machines are heated by steam coming from two steam generators of 600.000 Kcal/h each and refrigerated by a chilling tower of 960.000 Kcal/h

The osmotic water needed to produce one batch is dosed by an automatic flowmeter and it is introduced in the mixer already warm as the water pass through an AISI 316 steam/water heat exchanger. This operation allows considerable time saving: in one hour it is possible to have 9000 litres of water at 65°C.

This plant has been constructed according to the latest health regulations and requirements as to satisfy the most demanding customers; this plant has been approved by customers such as Procter & Gambler, Johnson & Johnson and Lever Fabergè.

.

gallery

gallery

contacts

Nuova Cosmar S.r.l.

Via Varese, 4 – 20063

Cernusco sul Naviglio (MI)

Tel: +39 02 92140846

Fax:+39 02 92370710

info@nuovacosmar.it

P.IVA e C.F. 09120880159

Nuova Cosmar S.r.l.

Via Varese, 4 – 20063

Cernusco sul Naviglio (MI)

Tel: +39 02 92140846

Fax:+39 02 92370710

info@nuovacosmar.it

P.IVA e C.F. 09120880159